产品中心

Product Center

Product details

1. Product Introduction

(1) Main content of the product:

UTG (Ultra Thin Glass) makes innovations in the field of consumer electronics a reality. It is currently mainly used in foldable mobile notebooks, tablet computers, mobile phones and smart wearable products. In the future, it can be applied to photovoltaic solar thin film batteries.

(2)Features

Compared with CPI (Clear PI), the UTG material, which is known to have good bending toughness, high transmittance and high hardness, is used through laser cutting, lamination mechanical cutting, and a variety of chemical treatments. After the unique ion-exchange glass chemical strengthening technology, the hardness and flexibility of the glass have been greatly improved again, and the number of bending times can reach UTG of more than 600,000 times.

When appropriate, AF+AR UTG is formed on the UTG touch surface by physical vapor deposition (PVD), so that a high transmittance AF with harder surface hardness, fingerprint oil resistance and stronger anti-interference ability can be obtained +AR UTG.

If necessary, the UTG with different surface resistance values can be obtained by using the existing physical vapor deposition metal non-conductive (NCVM) method to realize the function of anti-jamming signal.

2. Product details

(1)Technical route

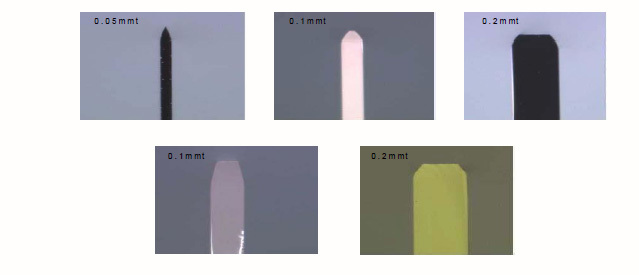

The glass below 0.1mm in thickness is thinned to below 0.1mm or the thickness required by customers through special chemical methods on the basis of glass sheets with thickness of 0.20-0.33mm, and 0.1mm, 0.07mm, 0.05mm, 0.03mm can also be used directly The original glass substrate of equal thickness is formed by one-time cutting, edging, chamfering, chemical strengthening, etc. by laser cutting, lamination, and circular knife cutting methods to obtain UTG that can be bent at least 400,000 times.

If it is necessary to improve the transmittance and tactility of UTG, additional processing methods: deposit AR layer by PVD method on the touch surface - deposit AF layer;

If it is necessary to protect the damage resistance of UTG, additional processing method: Use OCA (transparent optical adhesive) on the touch surface of UTG to paste AF+AR PET or CPI ultra-thin optical film coated with scratch-resistant coating.

(2) Product technical data

2.1 UTG types:

Most of them will use Corning or Schott's glass substrate, which can be suitable for folding displays after thinning.

2.2 Main technical data:

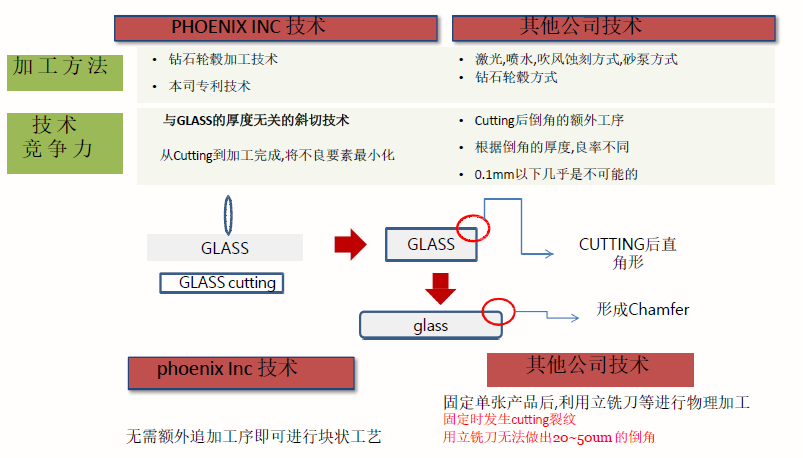

2.3 Laminated diamond cutting method Technical features:

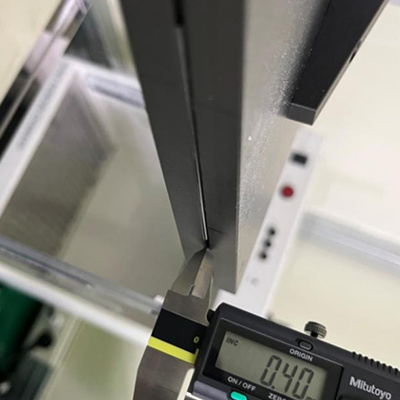

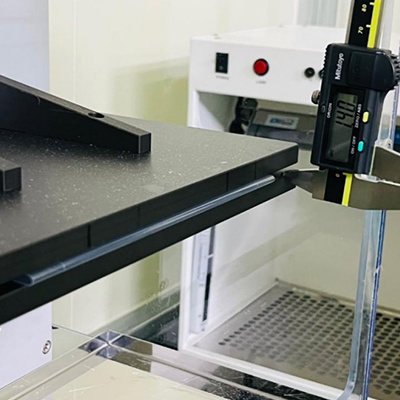

Improve yield and improve production efficiency process - accumulation layer process

●The accumulation layer process is the best method for thin film glass CUTTING and processing to maintain a high yield

●Possess bevel cutting technology in the state of accumulated layer glass

2.4 Comparison of cutting methods with competing products:

Compared with other competing companies that need to perform the next process of edge grinding and chamfering after cutting, the multi-layer lamination one-time cutting and chamfering greatly improves work efficiency and improves the yield.

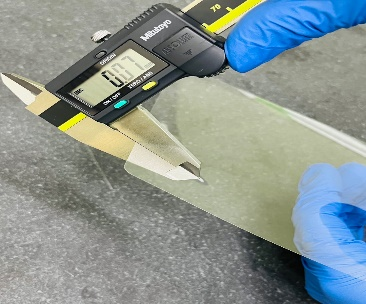

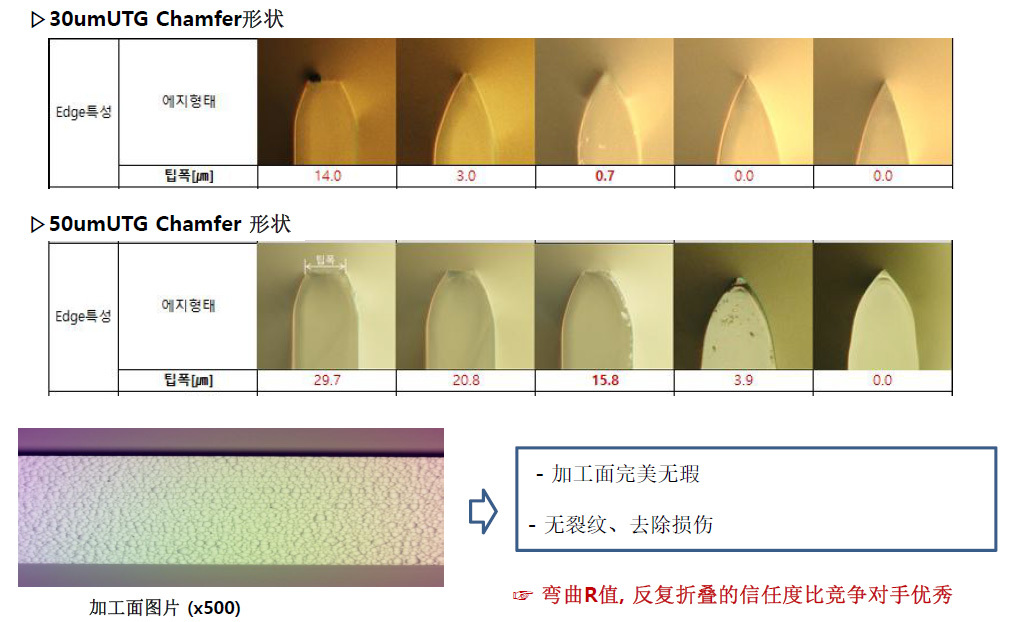

2.5 Processing the data of edge section:

· The shape of the edge of the processing surface can be freely selected

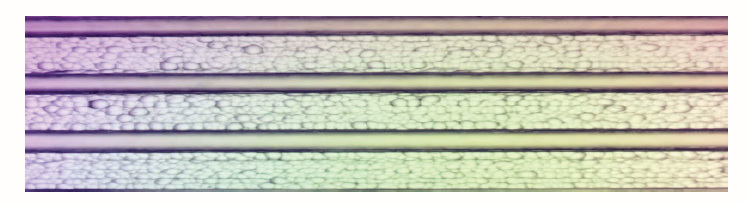

2.6 Glass section of core glass processing method:

· Beveled surface attached to the processed surface-relieve impact and pressure dispersion effect

· Flawless finish (no cracks, no damage)

· Protection of process steering wheel and GLASS surface - making higher yield

[Side image of each glass thickness - Chamfer form]

2.7 Glass product test data:

Redius (folding rate) Test

Static Bending Test

Drop ball test

Pen drop test

Test method: glass + front and back (no OCA, FILM)

3. Comprehensive comparison with similar products at home and abroad:

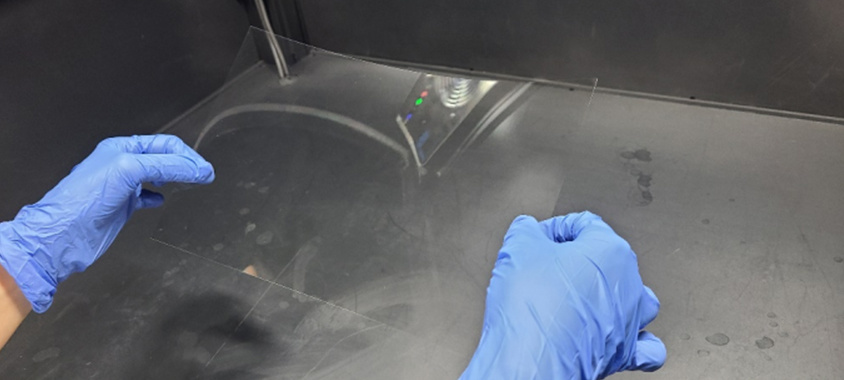

4. Relevant test pictures

Related products