产品中心

Product Center

External heating adsorption dryer

Category

Product accessories

Product details

Compressed air has become an indispensable working medium in all industrial fields in recent years. Its application occasions cover power air source, transportation air source, measurement air source, control and adjustment air source, etc. The ambient air sucked by the air compressor contains various harmful substances and impurities. However, the gaseous moisture will condense out of the pipeline and enter the downstream compressed air pipeline network, which will cause equipment damage and affect product quality, resulting in high economic losses. Therefore, the treatment of compressed air should include two concepts of filtration treatment and drying treatment.

The application determines the way of drying. Desiccant dryers are the best choice when extremely low residual moisture is required, especially when the pressure dew point is required to be below 0C.

Donaldson plans, designs and provides complete system solutions and related equipment for each customer's needs. Ensure your equipment has high reliability and operating efficiency.

Features of HRE series machines

High performance, high efficiency, high safety factor, easy maintenance, simple operation, no loss of compressed air;

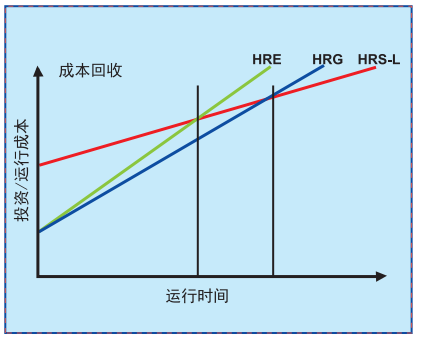

With the rapid development of science and technology, the technology of compressed air adsorption drying is also constantly developing. From the way of completely relying on compressed air for regeneration, it gradually develops towards the direction of regeneration without consuming any compressed air. Its development trend is to save energy consumption, lower operating costs, higher reliability, and easier maintenance. And Donaldson has always been at the forefront of this technology, constantly providing industrial customers with various economic system solutions to solve various problems.

Ultrafilter's HRE and HRG series external heating adsorption dryers heat the external ambient air, then use the heated ambient air to regenerate the adsorbent, and finally use a very small amount of compressed air to cool the regenerated adsorbent .

Ultrapac® HRE series machine performance characteristics:

|

•Related pressure vessels have Chinese import licenses. • The desiccant has a long durability and can be used normally for more than five years. •The gas flow rate is slow, the contact time with the adsorbent is long, and the adsorption efficiency is high. •The power of the heater can be adjusted according to the on-site operation conditions to reduce energy consumption. • A full set of Siemens PLC, reliable and safe control, with version upgrade technical support, to maintain upward compatibility. •Controller menu interface, the machi |

|

HRE series heat regenerative adsorption dryer

| Model |

Processing capacity |

Connection size DN |

Dimensions | Average power consumption KW |

weight kg |

||

| high (mm) |

long (mm) |

Width (mm) |

|||||

| 1000 1350 1650 1950 2250 2750 3500 4000 5000 6000 7000 8750 |

1000 1350 1650 1950 2250 2750 3500 4000 5000 6000 7000 8750 |

DN80 DN80 DN80 DN100 DN100 DN100 DN100 DN150 DN150 DN150 DN150 DN200 |

2679 2839 2839 2883 2939 2991 3112 3374 3527 3378 3431 3442 |

2017 2017 2067 2184 2217 2466 3483 3502 3677 3954 4079 4405 |

1250 1350 1362 1460 1480 1550 1693 1846 1846 1856 1892 2257 |

14.2 20.0 24.0 32.5 32.5 38.0 44.5 52.5 71.0 86.0 95.0 115.0 |

1210 1480 1790 2180 2360 2680 3180 3990 4820 5400 6200 8000 |

Flange interface size: HG20592

Maximum working pressure: 10bar(g)

Power supply: 3/380V/50Hz

Correction factor for sizing at -40°C pressure dew point

| Tlnlet | work pressurebar(g) | ||||||

| ℃ | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 30 | 0.72 | 0.92 | 1.09 | 1.25 | 1.36 | 1.45 | 1.51 |

| 35 | 0.55 | 0.7 | 0.86 | 1.00 | 1.12 | 1.25 | 1.37 |

| 40 | 0.33 | 0.45 | 0.58 | 0.71 | 0.82 | 0.92 | 1.03 |

| For example: (dew point -40°C) | Actual Air Flow (VT) | 3990m3/h |

| work pressure:6 bar(g) | Inlet temperature:40℃ | The conversion factor of the lookup table isC1:0.58 |

| Vr-VT/C1 =3990/0.58=6879m3/h | So choose:HRE7000 | |

Features of HRS-L series machines

The HRS-L dryer is based on the standard HRE dryer, and is designed and developed for the treatment requirements in tropical and subtropical climate conditions. In this model, the regeneration air whose temperature rises after passing through the high-temperature adsorbent passes through a water-cooled heat exchanger, and then returns to the inlet of the blower to prepare for the regeneration of the next cycle. This model can stably provide compressed air with a pressure dew point of -70°C under various climatic conditions around the world.

Characteristic

•Related pressure vessels have Chinese import licenses.

• Low system pressure.

• The desiccant has a long durability and can be used normally for more than five years.

•The gas flow rate is slow, the contact time with the adsorbent is long, and the adsorption efficiency is high.

•The power of the heater can be adjusted according to the on-site operation conditions to reduce energy consumption.

• A full set of Siemens PLC, reliable and safe control, with version upgrade technical support, to maintain upward compatibility.

•Controller menu interface, the machine running status is clear at a glance.

• Cooling air consumption is only zero.

• The structure of the whole machine is simple, and the maintenance is extremely convenient.

• Simultaneously have pressure dew point control and cycle time control. -40°C and -70°C models are available.

Selection Data Sheet

|

Model |

Processing capacity@7bar(g) |

Connection size HG20592 |

Total power KW |

Weight kg |

high (mm) |

long (mm) |

Width (mm) |

|

|

m3/h |

cfm |

|||||||

|

1000 |

1000 |

590 |

DN80 |

14.2 |

1900 |

2660 |

2280 |

1525 |

|

1350 |

1350 |

800 |

DN80 |

20.0 |

2200 |

2820 |

2285 |

1535 |

|

1650 |

1650 |

975 |

DN80 |

24.0 |

2400 |

2820 |

2445 |

1565 |

|

1950 |

1950 |

1150 |

DN100 |

32.5 |

2700 |

2990 |

2826 |

1585 |

|

2250 |

2250 |

1330 |

DN100 |

32.5 |

3050 |

3000 |

2850 |

1608 |

|

2750 |

2750 |

1620 |

DN100 |

38.0 |

3650 |

3030 |

2930 |

1660 |

|

3500 |

3500 |

2065 |

DN100 |

44.5 |

4700 |

3145 |

3681 |

2103 |

|

4000 |

4000 |

2360 |

DN150 |

52.5 |

5200 |

3430 |

3853 |

2150 |

|

5000 |

5000 |

2945 |

DN150 |

71.0 |

6400 |

3455 |

3700 |

2450 |

|

6000 |

6000 |

3535 |

DN150 |

86.0 |

7300 |

3310 |

4039 |

2495 |

|

7000 |

7000 |

4125 |

DN150 |

95.0 |

8300 |

3397 |

4035 |

2540 |

|

8750 |

8750 |

5155 |

DN200 |

115.0 |

10800 |

3525 |

4560 |

2970 |

Standard working conditions: compressor inlet temperature 20°C, inlet pressure 1 bar; dryer working pressure 7bar, outlet dew point -40°C

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| For example: (dew point -40°C) | Actual Air Flow (VT) | 3990m3/h |

| work pressure:6 bar(g) | Inlet temperature:40℃ | The conversion factor of the lookup table isC1:0.58 |

| Vr-VT/C1 =3990/0.58=6879m3/h | so choose:HRS-L7000 | |

Previous

Related products