产品中心

Product Center

VRS device

Category

Product accessories

The importance of the environment is increasing year by year, especially the environmental pollution of VOCs, which leads to environmental pollution, and disasters occur on many industrial sites, and the resulting industrial disasters are increasing rapidly every year.

Product details

The importance of the environment is increasing year by year, especially the environmental pollution of VOCs, which leads to environmental pollution, and disasters occur on many industrial sites, and the resulting industrial disasters are increasing rapidly every year.

Especially in the environment where various chemicals must be used in the semiconductor production process, the discharge of VOCs is high, especially in Display, the emission limit stipulated in the production process or the response to ISO 14001, the point of view of improving the working environment, the reduction of VOCs and Processing is required.

In the heavily polluted closed dust-free workshop, the particle pollution on the surface of the process equipment and products is intensified, and some secondary chemical reactions occur, which aggravates the pollution and causes defective products. The reduction of necessary volatile organic substances has a certain impact on the improvement of product yield. At present, VOCs generally use zeolite Roll structure, and the concentration rate of VOCs in this structure is limited to about 15 times. In order to overcome this problem, we have produced equipment with a Cylinder structure, and the concentration rate can reach 30 times.

Working Principle

Equipment Performance

Equipment Specifications

|

Distinguish |

Specification |

exam preparation |

|

|

Device name |

VRS – 350C |

|

|

|

Dimension |

W : 1700mm, H : 1700mm, L : 3800mm |

separate type |

|

|

Power Specifications |

Phase 3380V 50Hz 44KVA |

|

|

|

System |

PLC control (Mitsubishi) |

Be applicable Touch screen |

|

|

Process Fan & Motor |

Air Volume |

350 CMM |

Constant air volume |

|

Fan Positive pressure |

160mmAq |

PLENUM FAN |

|

|

Motor |

18.5KW X4P |

3Φ 380V 50Hz |

|

|

React Fan & Motor |

Air Volume |

9 CMM -17.5CMM |

variable air volume |

|

Fan Positive pressure |

140mmAq |

Turbo Fan |

|

|

Motor |

1.5kw |

3Φ 380V 50Hz |

|

|

Cylinder & Motor |

Cylinder |

Φ1420 , H:1040 |

Honeycomb Block Type |

|

Motor |

0.9kw |

chain drive |

|

|

React Heater |

23KW (regeneration temperature 210℃ ) |

1.27KW x18ea |

|

|

Automatic fire extinguishing equipment |

CO2 Automatic fire extinguishing equipment 14kgs |

CO2 Cabinet Type |

|

|

Auto Damper |

PRD Damper Type |

|

|

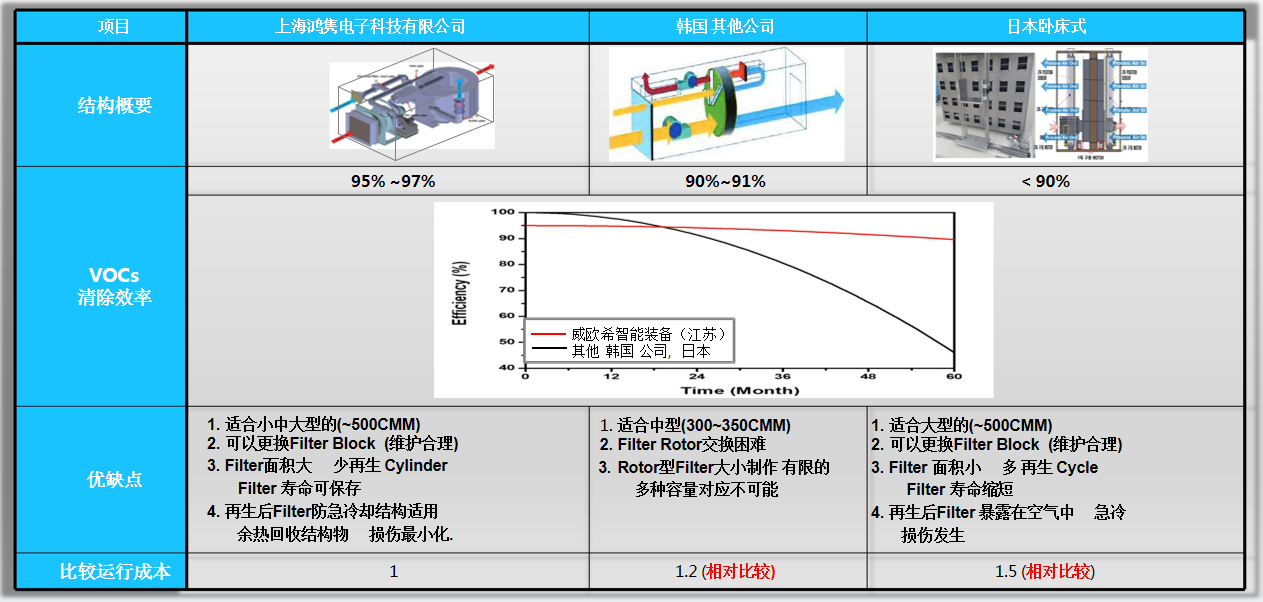

| VOC Reduction Efficiency | 90% OVER | Operate Normally over 95% | |

Device installation

Feasible solution recommendation

Considering the environmental conditions of the clean room (clean environment with constant temperature and humidity), as well as the composition, physical properties, and concentration values of pollution sources, the VOC removal schemes that can be adopted are basically locked in the concentration method, adsorption method and condensation method.

01: FFU+chemical filter (adsorption method), the chemical filter equipped with FFU, the filling amount of the adsorption material is limited and easy to absorb and saturate, it is suitable for occasions where the concentration of VOC in the environment is not high, usually in the crystal original semiconductor factory with advanced process technology, LTPS There are applications in factories and so on.

02: The air in the pollution source area is directly exhausted (displacement ventilation), and the air sent into the clean room needs to be heat-humidified and filtered. The cost of fresh air is high, and the direct discharge of polluted air will pollute the atmosphere. Usually used in test benches, small test areas, etc.

03: Add VOC treatment equipment (adsorption concentration) in the clean room. The concentrated high-concentration gas needs to be discharged through the organic exhaust system. The pollution source is usually equipped with an organic exhaust pipeline. If the organic exhaust system has a surplus, it can be connected. This solution is applied in Sansung and LGD LCD panel manufacturers.

Related products